Concentrating Solar + Thermal Storage, for a Low-Carbon Future

Heliogen’s next-generation concentrated solar solution combines precise mirrors and long-duration thermal storage with proven technologies like solar PV, AI and computer vision to advance clean energy deployment.

How it works

Harnessing the Power of the Sun at Industrial Scale

1. Computer-guided mirrors reflect sunlight to the receiver

As the sun moves, our computer vision system continuously measures the position of each heliostat for highest precision. This allows us to adjust and optimize the field, maximizing the energy collection throughout the day.

2. Receiver absorbs concentrated sunlight

The concentrated sunlight is then absorbed by a receiver at the top of a tower, generating high-temperature heat up to 1,000 °C —more than enough to power many industrial processes.

3. Heat transfers to thermal energy storage for dispatching

Thermal energy from the receiver is directed into a thermal energy storage system. From there, it can be dispatched at a range of temperatures for carbon-free energy when needed, with minimal interruption.

4. Steam on demand

Heat can then be converted to steam and supplied directly to the customer’s process, can turn a turbine to produce power, or can be used as feedstock in a solid oxide electrolyzer to produce green hydrogen.Autonomy & Robotics

High-Performing Smart Systems

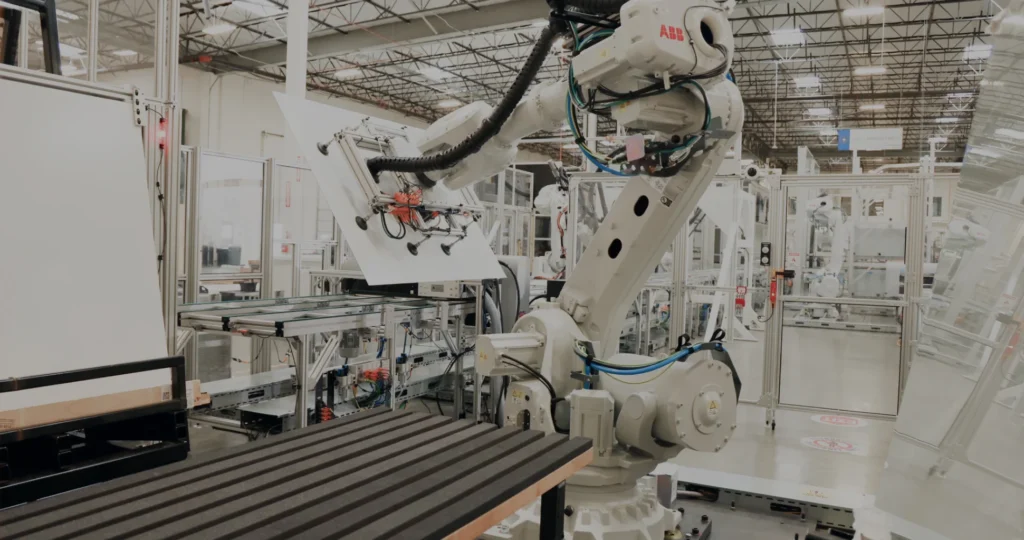

State-of-the-art heliostat manufacturing

Located in Long Beach, California, Heliogen’s large-scale, high-volume, automated production line enables high-speed manufacturing of heliostats. Our facility enables a significant cost advantage for heliostat production with controlled manufacturing conditions that output long-lasting, highly reliable, field-ready mirrors.

We manufacture for longevity and reliability in harsh outdoor environments. Environmental and accelerated life testing verify system performance for an expected 30-year life.

Continuous heliostat tracking with advanced computing and machine learning

Our core technology is the control system. Here’s how it works:

- Cameras installed at the top of the tower measure the color intensity of the sky as reflected in the mirrors.

- By comparing intensities as seen from multiple cameras, the technology calculates the mirror orientation and the direction of the beam, for real-time hyper-accurate tracking.

Continuous heliostat tracking with advanced computing and machine learning

Resilient in all conditions

The system automatically adapts to atmospheric conditions (wind, temp, etc.), reducing maintenance and recalibration.

More efficient field construction

AI Software

Machine-learning enabled

Heliogen’s heliostat tracking system has a built-in closed loop control system that tracks imperfect alignments quickly and adjusts heliostats automatically, eliminating the need for recalibration, saving time, capital, and human effort, and ensuring the heliostat field is always operating at peak performance.

Heliostats

Precise Heliostats to Point the Sun

A heliostat is a device that uses mirrors to track the sun’s movement and reflect sunlight towards a target. By tracking the sun, reflecting its energy, and concentrating it onto a receiver, each mirror is installed to maximize thermal energy collection.

The Benefits of our Heliostat Design

Small size

Heliogen’s smaller heliostats are designed to be easy to manufacture on an assembly line, shipped in a standard crate, and installed quickly without heavy equipment.

Rigorously tested

Accelerated aging and environmental tests validate heliostat real-world, difficult condition performance by simulating effects of wind, hail, dust, humidity, and freezing temperatures.

Optical accuracy

High receiver temperatures depend on optical accuracy. Our heliostats are designed to reduce errors in reflection and increase the amount of reflected sunlight to reach hotter temperatures.

Wireless, self-powered

Heliogen self-powered heliostats use solar energy. WiFi connects them wirelessly, reducing cabling needs, minimizing installation costs, and simplifying maintenance.

Video

Heliostats In Motion

Our latest heliostats are in use at our demonstration facility in Lancaster, CA, and will be mass-produced at our facility in Long Beach, CA.

Receiver tower

The Focal Point for Solar Thermal Energy

The receiver tower absorbs the concentrated sunlight from the heliostat field and generates heat for use. The heat can then be used to produce steam, green hydrogen, or electrical power as an alternative to fossil fuels.

Direct steam generation

Key capabilities:

Direct Steam Generating Receivers (DSGR) absorb concentrated sunlight and transmit the energy to pressurized water within metal tubes. This brings the water to a boil, generating steam which is transferred to the thermal energy storage system or directly to a customer facility.

Proven technology

DSGR is a low technical risk solution ready for immediate deployment.

Enables extended

hours operation

Stored steam can be dispatched when needed up to 15 Bar.

Enabling higher temperatures

Key Capabilities:

Heliogen is currently developing and testing a robust particle receiver that will enable the production of electricity and high-temperature industrial process heat. Particles directly absorb solar radiation, achieving rapid heat transfer and high receiver efficiency.

- Solid particles, such as sintered bauxite, are routed into a centrifugal receiver.

- As the receiver turns, the particles absorb concentrated sunlight, heating them to high temperature.

- Hot particles are then transferred into an insulated silo for industrial use and energy storage.

- Molten salt receivers have been successfully deployed globally for decades.

- Uses molten nitrate salts which operate at up to 565 °C (1050 °F)

- Non-reactive under normal circumstances.

Other receivers in development

Heliogen is continuously developing new ways to meet industrial energy needs. We are working on receivers that will support high temperature processes like calcination.

Thermal energy storage

Enabling

On-Demand Energy

A major barrier to the widespread adoption of green alternatives is the difficulty at maintaining a steady renewable energy supply.

Heliogen aims to solve the storage challenge by taking full advantage of overgeneration on sunny days, storing heat to use at night or on cloudy days. We use cost-effective materials that sustain key processes during extended hours of operation.

Proven steam generation

Key capabilities:

Steam accumulators have been used to store industrial heat for over a century. By pairing them with a solar thermal Direct Steam Generating Receiver, the sun’s energy can be stored as steam to serve industrial processes running day or night.

Sustainable, cost-effective materials

Key capabilities:

Heliogen systems use economical, readily available solids, like ceramic particles, as a storage medium. The particles are directly heated and then gravity-fed into insulated silos for thermal energy storage. With modular design, storage capacity can scale up or down with relative ease.

Optimized heat storage

Key capabilities:

Molten salt is the energy storage technology of choice for solar thermal projects worldwide due to its stability at high temperatures and high heat capacity.Technology Integrations

Taking Renewable Energy a Step Further

Electrolyzers

Solid oxide electrolyzers (SOEC) use steam as feedstock to replace more expensive electrical energy with inexpensive thermal energy.

Power

Blocks

Electrolyzers